Turnout Material Selection Guide

Composite Systems

Before choosing which turnout materials make up the right combination for your department's safety, you need to understand how they work together as a composite system.

What is a composite system? All fire suits are made up of 3 layers; the outer shell, moisture barrier, and thermal liner. When talking about these 3 fabrics together, we refer to them as a composite system. It is not possible to build safe gear that meets all NFPA requirements without one of these layers. Therefore, it is extremely important that each layer works well together to provide balanced protection.

Composite systems determine:

- How much the overall turnout gear will weigh

- How easily your body will be able to self regulate back to a normal temperature

- How much heat your turnout gear will endure while protecting you

- How much strength it'll take for an object to penetrate through the protective layers

- How easily you'll be able to move through a fire scene

Deciding on the right composite system for your fire department begins with determining your needs, then finding a suitable balance.

Trim Selections

Level up your on-scene safety with our durable and vibrant trim options, designed to pair either your turnout gear or alternative PPE

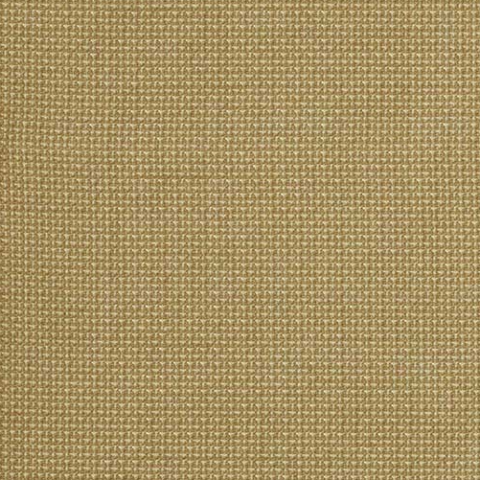

TECGEN71®

-

Gold

Gold

-

Black

Black

AGILITY™

-

Light Gold

Light Gold

-

Dark Gold

Dark Gold

-

Black/Gold

Black/Gold

ARMOR™ AP

-

Gold

Gold

-

Black

Black

-

Khaki

Khaki

Gentex® Dual Mirror® Aluminized Fabric

-

Aluminized

Aluminized

PBI® XT

-

Gold

Gold

-

Black

Black

FLex7™ FLEX

-

Gold

Gold

-

Black

Black

NOMEX® Essential

-

Yellow

Yellow

-

Tan

Tan

-

Black

Black

-

White

White

-

Red

Red

-

Navy

Navy

PBI MAX® LP

-

Gold

Gold

-

Black

Black

PBI MAX® 7oz

-

Gold

Gold

-

Black

Black

PBI Peak5® 5.6oz

-

Natural

Natural

-

Black

Black

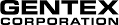

PIONEER™

-

Gold

Gold

-

Khaki

Khaki

-

Yellow

Yellow

-

Black

Black

-

Light Gold

Light Gold

-

CROSSTECH® 3-Layer

Substrate : NOMEX® fabric woven from spun fibers (pajama check on front, proprietary weave on back)

Membrane: Enhanced bicomponent GORE™ ePTFE film

Total Weight : 7.0 oz/yd2

Supplier Warranty : 7 years

-

CROSSTECH® BLACK

Substrate : NOMEX® fabric woven from spun fibers (pajama check)

Membrane: Enhanced bicomponent GORE™ ePTFE film

Total Weight : 4.7 oz/yd2

Supplier Warranty : 5 years

-

Gore® RT7100

Substrate :Nomex® nonwoven substrate

Membrane: Enhanced bicomponent GORE™ ePTFE film

Film : Bi-component ePTFE membrane

Total Weight : 4.6 oz/yd2

Supplier Warranty: 4 years

-

STEDAIR® Clear™️

Substrate : NOMEX® woven pajama check

Film : Non-fluorinated membrane

Total Weight : 6.5oz/yd2

Supplier Warranty : 3 years

-

STEDAIR® 3000

Substrate : NOMEX® non-woven spun lace

Film : Bi-component ePTFE membrane

Total Weight : 5.2 oz/yd2

Supplier Warranty : 4 years

-

STEDAIR® 4000

Substrate : NOMEX® woven pajama check

Film : Bi-component ePTFE membrane

Total Weight : 5.5 oz/yd2

Supplier Warranty : 5 years

-

STEDAIR® GOLD

Substrate : PBI®/NOMEX® blend non-woven spun lace

Film : Bi-component ePTFE membrane

Total Weight : 5.2 oz/yd2

Supplier Warranty : 7 years

-

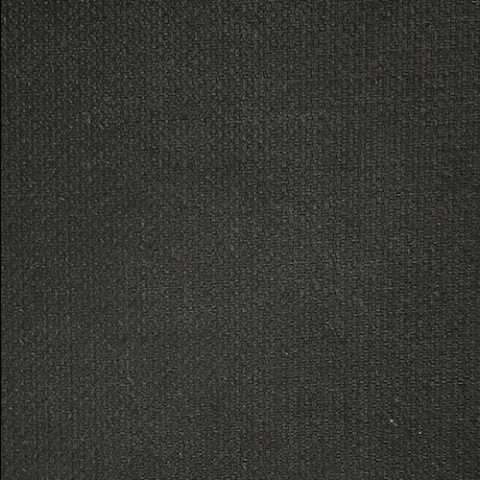

DEFENDER™ M ELITE NP

Face Cloth : LENZING FR®/Aramid/Nylon blend spun yarn, plain weave. Available in brass.

Batting : 1 layer aramid needle punch

Total Weight : 7.0 oz/yd2

-

GLIDE ICE™ 1-LAYER

Face Cloth : 3.6 oz/yd2 86% Aramid/14% Viscose Twill Weave

Batting : Quilted 1 layer of 2.3oz/yd2 Aramid

Total Weight : 5.9 oz/yd2

-

GLIDE ICE™ 2-LAYER

Face Cloth : 60% NOMEX® filament yarn with 40% NOMEX®/LENZING FR® blend spun yarn, twill weave

Batting : 2 layers of NOMEX® E89™ spunlace (1 layer each of 2.3 and 1.5 oz/yd2)

Total Weight : 7.4 oz/yd2

-

GLIDE ICE™ NOMEX® NANO

Face Cloth : 60% NOMEX® filament yarn with 40% NOMEX®/LENZING FR® blend spun yarn, twill weave

Batting : 2 layers of NOMEX® E89™ spunlace (1 layer each of 2.3 and 1.5 oz/yd2)

Total Weight : 7.4 oz/yd2

-

Milliken® CoreCXP™ 2-Layer

Face Cloth : 100% spun Nomex®

Batting : 2 layers of spunlace E-89

Total Weight : 7.1 oz/yd2

-

Milliken® CoreCXP™ 1-Layer

Face Cloth : 100% spun Nomex®

Batting : 1 layer of spunlace E-89

Total Weight : 5.6 oz/yd2

-

PRISM™ 1-LAYER

Face Cloth : 3.6 oz/yd2 68% Aramid/21% FR Viscose/11% Polyamide Dobby Weave

Batting : Quilted 1 layer of 2.3oz/yd2 Aramid

Total Weight : 5.9 oz/yd2

-

Q-8™

Face Cloth : Meta-aramid, FR modacrylic (spun)

Batting : Aramid, FR rayon, needle-punch, non-woven

Total Weight : 8.0 oz/yd2 -

QUANTUM 4I™ SL2i

Face Cloth : KEVLAR® filament yarn with LENZING FR®/KEVLAR®/Nylon spun fibers, check weave

Batting : Two layers of aperture PBI®G2™ spun laceTotal Weight : 7.0 oz/yd2

-

TITANIUM™

Face Cloth : Filament Nomex® and COOLDERM™ technology

Batting : 2-layer, spun lace

Total Weight : 7.7 oz/yd2