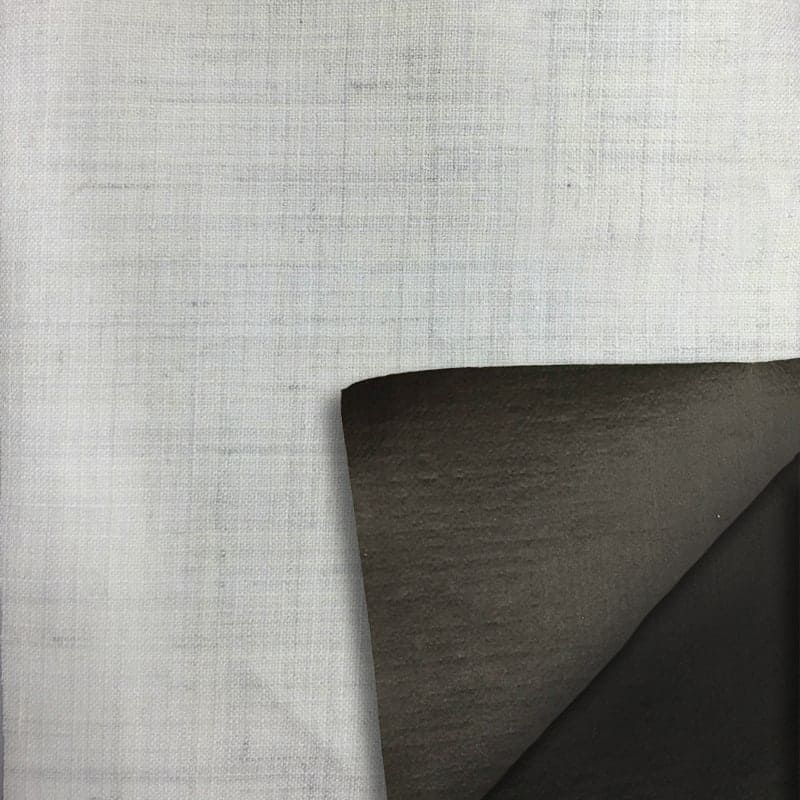

TECGEN71® Outer Shell

TECGEN71® IS THE ONLY OUTER SHELL THAT CAN BE PAIRED WITH

THE LIGHTEST THERMAL LINERS AND MOISTURE BARRIERS AVAILABLE ON TODAY'S MARKET

DUE TO ITS INCREASED BREATHABILITY AND THERMAL PROTECTION.

OUR FOCUS IS ON HEAT STRESS

Heat stress contributes to serious health conditions, including heat stroke, cardiac fatigue and cardiovascular failure. It occurs when the body's temperature rises rapidly and is unable to self-regulate back to its core temperature.

Given the strenuous nature of the job, firefighters are exposed to heat stress far more often than the general public. As the #1 cause of LODDs worldwide, it was important to Fire-Dex to revolutionize the way we manufacture turnout gear.

Our TECGEN71® outer shell is the first of its kind to address this growing health concern with innovative technology aimed at providing the perfect balance of breathability, comfort, TPP and THL, all while offering an overall reduction in composite weight.

-#1 CAUSE OF LODDs-

-59% OF LODDs-

-FIRE-DEX's DEDICATION-

"I can tell you after wearing this gear for two years that I can do more burns, evolutions, in one day, than in some gear that's overbuilt to protect you thermally but doesn't think about your body's physiology and all the stress placed on it."

ANDY STARNES - FOUNDER - INSIGHT TRAINING LLC

GEAR WASH PPE CLEAN & REPAIR

Ensure your gear stays in peak performance and lasts longer by keeping up with regular PPE cleaning & maintenance services!

We teamed up with Milliken, a global research and innovation leader with over 50 years of expertise in FR fabric manufacturing to achieve a common goal: to protect those who protect us.

The resulting TECGEN71® fabric was revolutionary to the PPE industry, opening new opportunities for us to improve upon the health and safety solutions offered to first responders worldwide!

- MATERIAL OFFERINGS -

View all available composite systems and choose the one that best suits your department.

TECGEN71 COMPOSITE PERFORMANCE REVIEW

| COMPOSITE SYSTEMS | TOTAL COMPOSITE WEIGHT (OSY) | THERMAL PROTECTIVE PERFORMANCE (TPP) | TOTAL HEAT LOSS (THL) | RESISTANCE TO EVAPORATE HEAT LOSS (RET) |

|---|---|---|---|---|

| TECGEN71® CORECXP™ 1-LAYER STEDAIR® 4000 | 17.7 | 37.5 | 348 | 15 |

| TECGEN71® GLIDE ICE™ 1-LAYER STEDAIR® 4000 |

17.9 | 41.4 | 317 | 21 |

| PBI® MAX 6.0 GLIDE ICE™ 2-LAYER STEDAIR® 4000 |

18.9 | 38.9 | 269 | 24 |

| PBI® PEAK5 TITANIUM SL2i STEDAIR® 4000 | 19.1 | 37.8 | 274 | 21 |

| TECGEN71® CORECXP™ 2-LAYER STEDAIR® 4000 | 19.2 | 46.1 | 288 | 18 |

| ARMOR AP GLIDE ICE™ 2-LAYER STEDAIR® 4000 |

19.4 | 39.2 | 269 | 24 |

| AGILITY TITANIUM SL2i STEDAIR® 4000 | 19.8 | 39.3 | 288 | 22 |

| PIONEER TITANIUM SL2i STEDAIR® 4000 | 19.8 | 41.6 | 288 | 22 |

| PBI® MAX 7.0 GLIDE ICETM 2-LAYER STEDAIR® 4000 |

19.9 | 42.4 | 273 | 25 |

| TECGEN71® CORECXP™ 1-LAYER CROSSTECH® BLACK | 16.9 | 35.0 | 340 | 19 |

| TECGEN71® PRISM™ 1-lAYER CROSSTECH® BLACK |

17.1 | 37.9 | 318 | 20 |

| TECGEN71® GLIDE ICE™ 1-LAYER CROSSTECH® BLACK |

17.1 | 38.6 | 315 | 23 |

| TECGEN71® GLIDE ICE™ NOMEX® NANO CROSSTECH® BLACK |

17.8 | 41.6 | 313 | 24 |

| PBI® MAX 6.0 GLIDE ICE™ 2-LAYER CROSSTECH® BLACK |

18.1 | 35.1 | 274 | 30 |

| TECGEN71® CORECXP 2-LAYER CROSSTECH® BLACK | 18.6 | 43.9 | 297 | 22 |

| TECGEN71® GLIDE ICE™ 2-LAYER CROSSTECH® BLACK |

18.6 | 43.1 | 281 | 26 |

| ARMORTM AP GLIDE ICE™ 2-LAYER CROSSTECH® BLACK |

18.6 | 35.0 | 270 | 29 |

| AGILITY™ CALDURA® SL2i CROSSTECH® BLACK | 19.0 | 41.1 | 282 | 26 |

| PIONEER™ CALDURA® SL2i CROSSTECH® BLACK | 19.1 | 38.0 | 269 | 26 |

| PBI® MAX 7.0 GLIDE ICE™ 2-LAYER CROSSTECH® BLACK |

19.1 | 38.9 | 278 | 28 |